Article Introduction

Thank you for your interest in our website. Have you ever encountered such a situation? When installing PVC pipe fittings,especially when installing elbow pipes, it may be difficult to fit between the pipes. This is because the angle of the PVC pipe elbow fitting is not suitable. The next article will solve the problem of the angle of the PVC pipe elbow fittings degrees.

What are the PVC pipe elbow fittings angle degrees

1. The elbow angle of PVC pipe fittings has 90 degrees, 45 degrees, 135 degrees, U type and S type, and adopts rigid PVC or PVC-U pipes.

2. 90 and 45 degrees are used for drainage. U and S are mostly used for storing water and separating odour.

3. Application of elbow: 90 degrees and 45 degrees are applied to pipe ends turning. The actual work experience shows that the 90 degree elbow occupies small space, the circulation effect and the impact force are greater; the 45 degree elbow occupies large space, but the circulation effect is good, if the space position is large, it is suggested that the 45 degree elbow butt into the large arc curve. The U, S and P water storage curves are all water retaining and odorizing functions. For example, the kitchen sink is drained with S type water storage bend, and the urinal drain is connected with the P type storage water bend. The washbasin drainage is often connected with the U type storage water bend. No matter what kind of water storage elbow it is, it can achieve good odor isolation effect as long as the water level is kept.

4. In addition, it is necessary to pay attention to the project of changing the pipe in the house. The drop of the water in the pool must be enough, otherwise it is easy to cause the slow drainage of the toilet, and it is easy to plug the fault for a long time.

How to connect elbow to PVC pipe?

Connecting an elbow to a PVC pipe is a common step in plumbing systems to change the direction of flow. Here’s a simple step-by-step guide to do it correctly:

🔧 Materials You’ll Need:

- PVC pipe

- PVC elbow (usually 90° or 45°)

- PVC primer (optional but recommended)

- PVC cement (solvent glue)

- Pipe cutter or hacksaw

- Rag or sandpaper

🧰 Step-by-Step Instructions:

1. Measure and Cut the Pipe

- Measure the length of PVC pipe you need.

- Cut it squarely using a PVC cutter or fine-tooth saw.

- Remove burrs or rough edges with sandpaper or a utility knife.

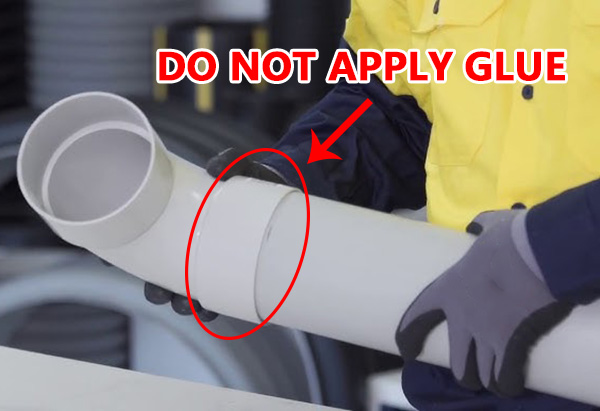

2. Dry Fit the Pieces

- Insert the PVC pipe into the elbow without glue to make sure it fits.

- Ensure the angle is correct for your layout.

3. Clean the Joints

- Wipe the pipe and elbow sockets clean with a rag.

- For best results, use PVC primer on both the pipe end and the inside of the elbow fitting.

4. Apply PVC Cement

- Apply a thin, even layer of PVC cement to both the pipe and the elbow.

- Be quick—PVC cement sets fast!

5. Connect the Pieces

- Immediately push the pipe into the elbow socket.

- Give it a quarter-turn twist to evenly spread the cement.

- Hold firmly for 15–30 seconds until it sets.

6. Let It Cure

- Let the joint cure for at least 15 minutes before handling.

- Wait 2 hours (or follow label instructions) before turning on water pressure.

✅ Pro Tips:

- Work in a well-ventilated area (PVC cement has strong fumes).

- Use primer especially for high-pressure or long-lasting installations.

- Don’t use excessive cement—drips inside the pipe can cause flow restriction.

- If you’re working on pressurized systems, consider using Schedule 40 or Schedule 80 fittings depending on pressure rating.

Characteristics of PVC pipe fittings

1. Fluid resistance is small: the tube wall of PVC-U pipe is very smooth, the resistance to the fluid is very small, its roughness coefficient is only 0.009, its water transport capacity can be increased by 20% than the same pipe diameter cast iron pipe, and 40% higher than that of the concrete pipe.

2. It has better tensile and compressive strength, but its flexibility is not as good as other plastic pipes.

3. Has good water tightness: the installation of PVC-U pipes, regardless of whether they are bonded or rubber rings, have good watertightness.

4. Corrosion resistance, good resistance character: PVC-U pipe has excellent acid resistance, alkali resistance, corrosion resistance, not affected by moisture and soil pH, without any antiseptic treatment in pipeline laying.

5. Performance test: curing time, shrinkage rate, splitting strength, tensile property, peel strength, thermal stability, application period, storage period, release of harmful substances.

6. Bite: PVC-U tube is not a nutrient source, so it will not be eroded by rodents. According to the experiments conducted by the National Health Foundation in Michigan, rats do not bite PVC-U pipes.

summarize

If you need your piping system to get turn or get around something in the way, you will need to bend your pipeline around with PVC elbows. The elbow angle of PVC pipe fittings has 90 degrees, 45 degrees, 135 degrees, U type and S type, and adopts rigid PVC or PVC-U pipes. so your pipeline can be directed however you want it.

If you want to learn more about related content knowledge, or have the intention to purchase PVC pipes and fittings, you can always consult us (SAM-UK) for more information!

About SAM-UK

SAM-UK are a professional 18+ years manufacturer in producing vinyl building profile products and PVC , CPVC , PPH , PPR , PP pipes and pipe fittings, valves, taps and so on. We own the certificates of SGS\SONCAP\ISO9001\CE\NSF,support color /size customization. Welcome to consult for Catalog and Product. you can contact us at email [email protected]