SAM-UK are a professional manufacturer in producing vinyl building profile products and PVC,CPVC, PP ,PPR pipes and pipe fittings, valves, taps and so on .We own the certificates of SGS\SONCAP\ISO9001\CE\NSF.

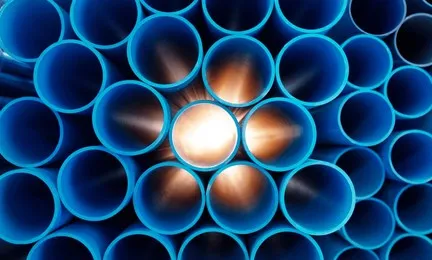

Introduction of plastic pressure pipe

Plastic pressure pipe is a new type of pipe, which has the advantages of light weight, convenient installation and high cost performance. Compared with traditional steel pipes and cast iron pipes, plastic pressure pipes have better corrosion resistance and chemical resistance to prevent rust and corrosion in the pipes. At the same time, the construction cost of plastic pressure tubes is also lower, and the service life is longer.

Heat resistant temperature range of plastic pressure tubes

Under normal circumstances, the heat resistance temperature range of plastic pressure tubes depends on its material. In general, the heat resistance temperature range of PE pipes is between -40 ° C and 60 ° C, PP pipes are between 0 ° C and 70 ° C, and PVC-U pipes are between 0 ° C and 45 ° C. The heat resistant temperature range of these materials can meet general industrial requirements.

However, it should be noted that when the use temperature of the plastic pressure pipe exceeds its heat-resistant temperature range, the pipe may be deformed or broken. Therefore, when using plastic pressure pipes, the pipe material that meets the requirements should be selected, and the use temperature should not exceed its heat-resistant temperature range.

Other considerations

In addition to the material and temperature of the pipe, the design and construction of the pipe are also crucial. Reasonable pipeline design can reduce the degree of pipeline heating, thereby reducing the risk of pipe heating. At the same time, the correct construction can also ensure the quality of the pipeline connection and avoid the temperature of the pipeline due to the connection problem.

In short, the heat resistance temperature range of the plastic pressure pipe depends on its material, and it needs to be selected according to the specific situation. When in use, attention should be paid to controlling the use temperature of the pipeline, avoiding exceeding its heat-resistant temperature range, and ensuring the design and construction quality of the pipeline.